Chinese wholesale Plastic Pot Making Machine - MTC 400 Full Servo Automatic Cutting Machine – Mengxing

Chinese wholesale Plastic Pot Making Machine - MTC 400 Full Servo Automatic Cutting Machine – Mengxing Detail:

Machine Details

Feature

01. This machine mechanical, pneumatic, electrical integration. Each action program controlled by the PLC. Touch-screen operation, simple and convenient.

02. servo motors sheet feeding, step-less adjustment of length, speed accuracy and stability.

03. Adapt with ordinary plastic machine, vacuum forming machine connections are trimmed.

04. Cutting using laser cutter mold, the lower the cost.

05. Using die cutting technology shift, little can be achieved without cutting plastic products, in line with most of the food packaging requirements.

06. Cutting clamping down with full servo drive, fast and precise clamping stroke.

07. Robot sucked out barrier stack, saving labor costs, reduce labor intensity.

08. Using quick die change equipment, pneumatic clamping.

Technical Parameters

| Parameter | MTC 400(mode No.) | |

| Max. cutting area(mm2) | 400 × 760 | |

| Available sheet thickness (mm) | 0.3-1.5 | |

| Available sheet width (mm) | 500-800 | |

| Max. cutting force (ton) | 45 | |

| Upper mould stroke(mm) | 80 | |

| Under mold stroke (mm) | 110 | |

| Max.height of product (mm) | 70 | |

| Max.depth of product (mm) | 100 | |

| Capacity (Cycle/min) | 30 | |

| Gas source (outlay) | Air supply(m3/min) | ≥ 3 |

| Pressure(MPa) | 0.8 | |

| Power supply | three-phase four-wire

380V / 220V 50Hz |

|

| Motor power(Kw) | 19 | |

| Max. power of whole machine(Kw) | 21 | |

| Dimensions (L × W × H) (mm) | 4500 × 3100 × 2900

(including motor height) |

|

| Total Weight (Kgs) | 5500 | |

Technical Configuration

| Programmable Logic Controller (PLC) | Taiwan Delta |

| 10.4 inches color touch screen | Taiwan Delta |

| Sheet feeding servo motor (1.0kw) | Taiwan Delta |

| Up mold servo motor (5.5kw) | Taiwan Delta |

| Down mold servo motor (4.5kw) | Taiwan Delta |

| AC contactor | Germany Siemens |

| Thermal relay | Germany Siemens |

| Intermediate relay | Germany Weidmuller |

| pneumatic components | Japan SMC |

| Cylinder | China |

Our Advantage

With excellent management, strong technical ability and strict control methods, Mengxing provides customers with responsible high-quality products. We can become one of your most responsible partners and provide you with full-automatic high-speed garbage bag bottom sealing machine, thick and heavy plastic bag making machine, heat sealing and cold cutting machine, which is our great honor to meet your needs.

In the spirit of “reputation first, innovative development, sincere cooperation, and common growth”, our company strives to create a brilliant future with you!

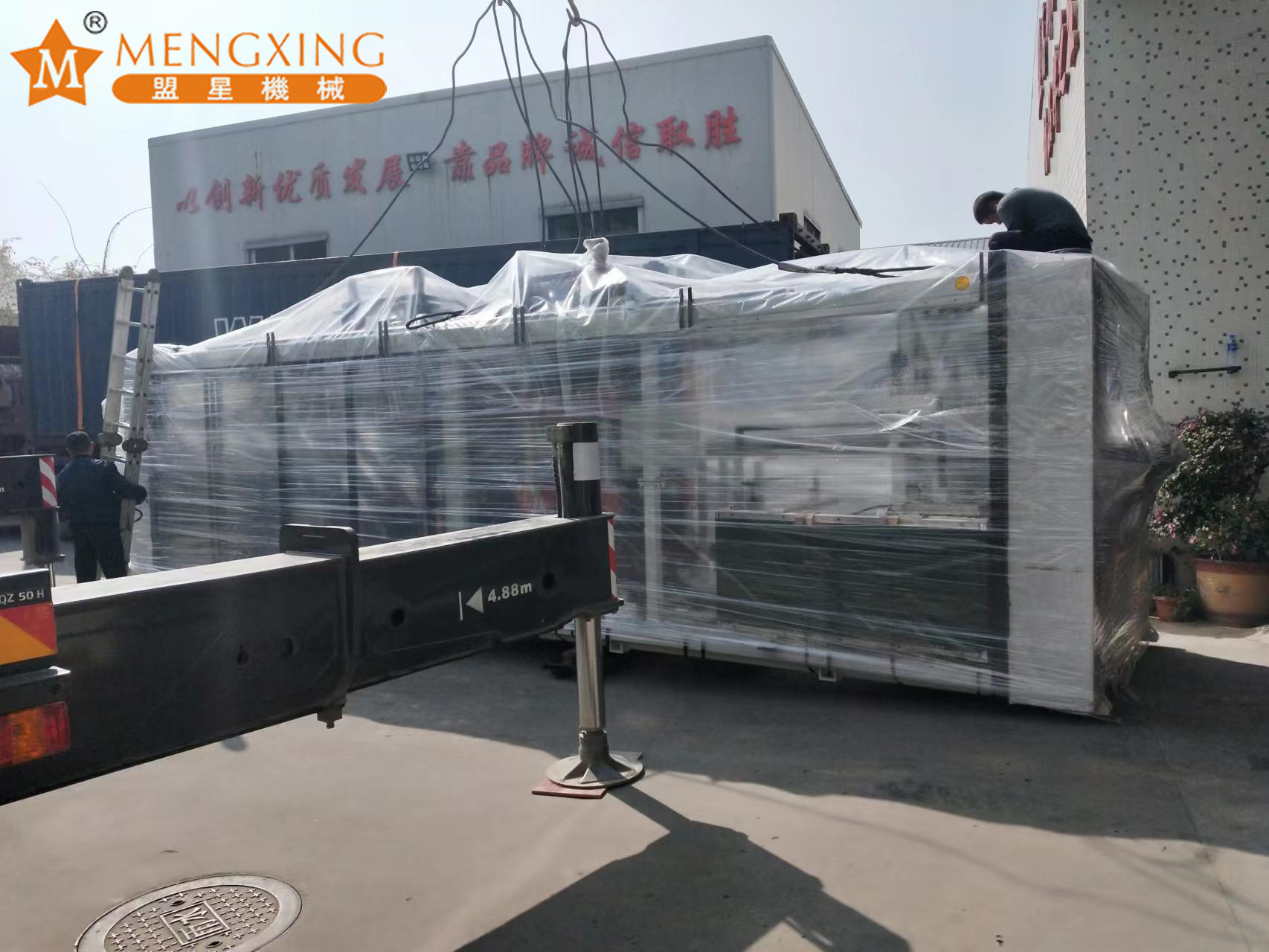

Container Pictures

Product detail pictures:

Related Product Guide:

We constantly function like a tangible group to ensure that we can give you the very high-quality and also the very cost for Chinese wholesale Plastic Pot Making Machine - MTC 400 Full Servo Automatic Cutting Machine – Mengxing , The product will supply to all over the world, such as: Costa rica, Jeddah, Las Vegas, The design, processing, purchasing, inspection, storage, assembling process are all in scientific and effective documentary process , increasing usage level and reliability of our brand deeply, which makes us become superior supplier of the four major product categories shell castings domestically and obtained the customer's trust well.

Good quality, reasonable prices, rich variety and perfect after-sales service, it's nice!