factory Outlets for Semi Automatic Thermoforming Machine - MFC9070 3 Stations Thermoformer – Mengxing

factory Outlets for Semi Automatic Thermoforming Machine - MFC9070 3 Stations Thermoformer – Mengxing Detail:

Machine Details

Usage

The machine is designed for producing various of open-wide plastic containers, such as food trays, plastic trays, cosmetic trays, blister, clamshells, plates and other plastic related items .

Suitable Sheet

PVC, PP, PS, OPS, PET, APET, PETG, CPET Etc.

Structure Features

1.Mechanical, pneumatic and electrical combination, all working actions are controlled by PLC. Touch screen makes the operation convenient and easy.

2.Pressure And/Or Vacuum forming.

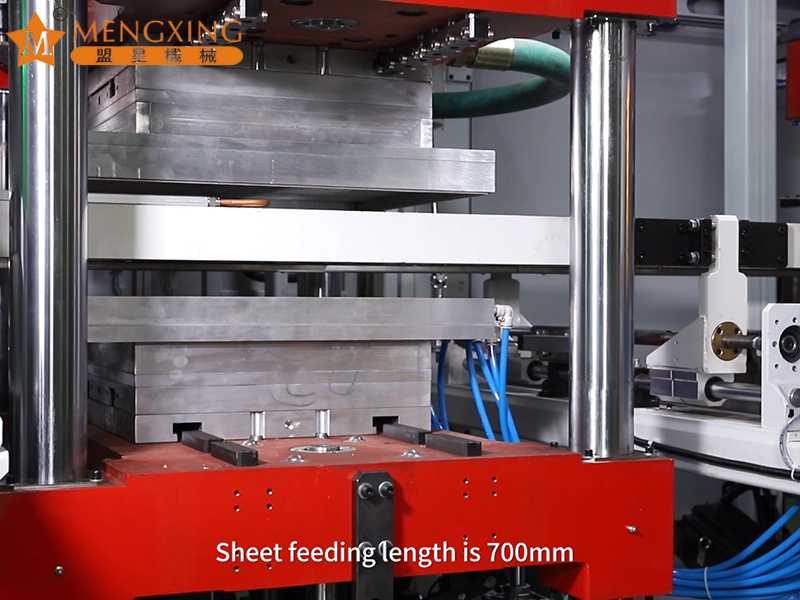

3.Up and down mold forming method.

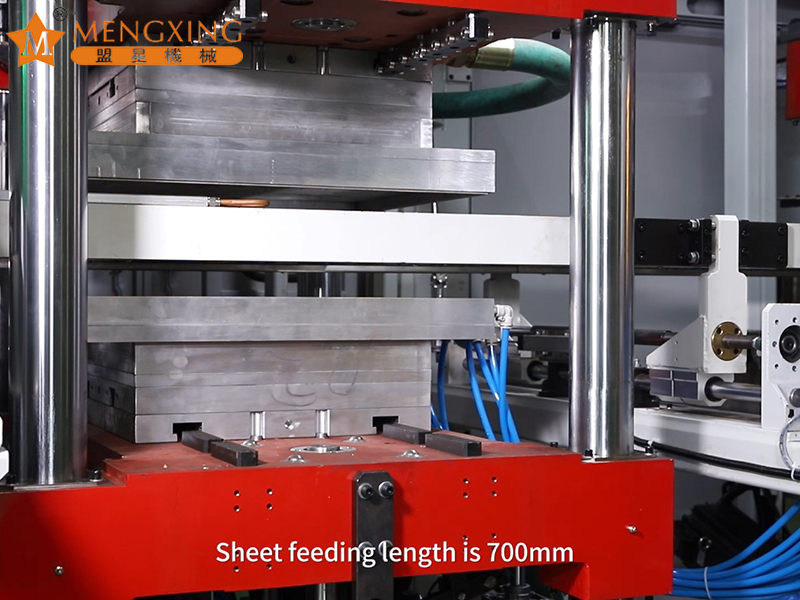

4.Servo motor feeding, feeding length can be step-less adjusted. High speed and accurate.

5.Upper & lower heater, three sections heating

6.Heater with intellectual temperature control system, automatic supply the heating individual heater control. Fast heating(3 min from 0-400 degree), it won’t be effected by outer voltage.

7.Forming and cutting unit mold open and close controlled by servo motor, products automatically count.

8.Data memorization function can store 120 set of running data.

9.Stacking type: downward stacking/Robot Stacking.

10.Feeding width can be synchronously or independently adjusted in electrical way.

11.Oven will automatically push-out when the sheet is over heated, Air pressure not enough.

12.Automatic lubrication system.

13.Quick mold change system, Auto roll sheet loading, reduce the working load.

Technical Parameter

| Sheet width (mm) | 540-940 | |

| Sheet thickness (mm) | 0.1-1.5 | |

| Max roll sheet diameter (mm) | 800 | |

| Forming mold stroke (mm) | (Up ) 170,(down) 170 | |

| Mold clamping force(ton) | 80 | |

| Max forming area (mm2) | 900×700 | |

| Min forming area (mm2) | 500×400 | |

| Forming mold width (mm) | 500-900 | |

| Forming mold length (mm) | 400-700 | |

| Max forming depth/height (mm) | 155 / 155 | |

| Cutting mold stroke(mm) | (up)170,(down)170 | |

| Max cutting area (mm2) | 900×700 | |

| Cutting force(ton) | 100 | |

| Cycle (time/ min) | Robot Stacking Max17

Downward Stacking Max40 |

|

| Cooling | Water cooling | |

| Air supply | volume (m3/ min) | ≥2 |

| Air pressure (MPa) | 0.8 | |

| Vacuum pump | Busch R5 0100 | |

| Power supply | 3 phase 4 line 380V50Hz | |

| Heater power (kw) | 145 | |

| Max general power (kw) | 190 | |

| Dimension (L×W×H) (mm) | 13400×3000×3230 | |

| Weight ( T ) | ≈25 | |

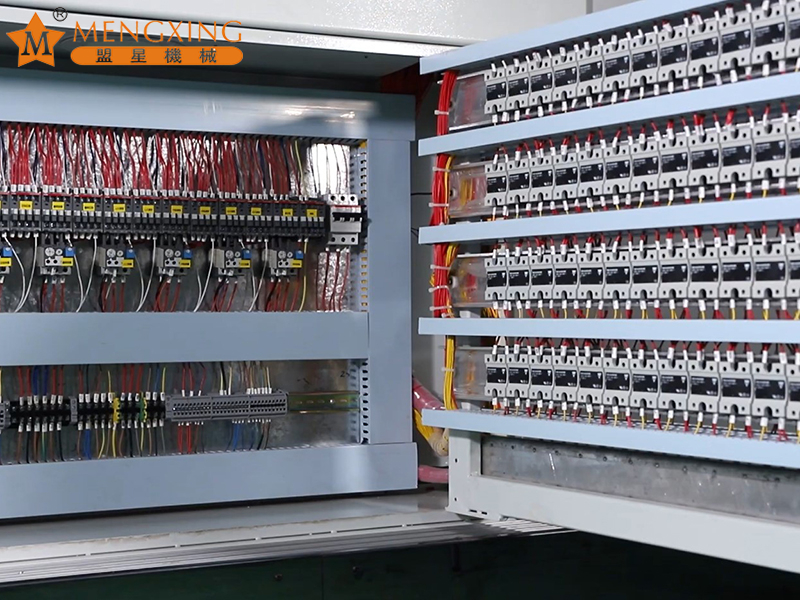

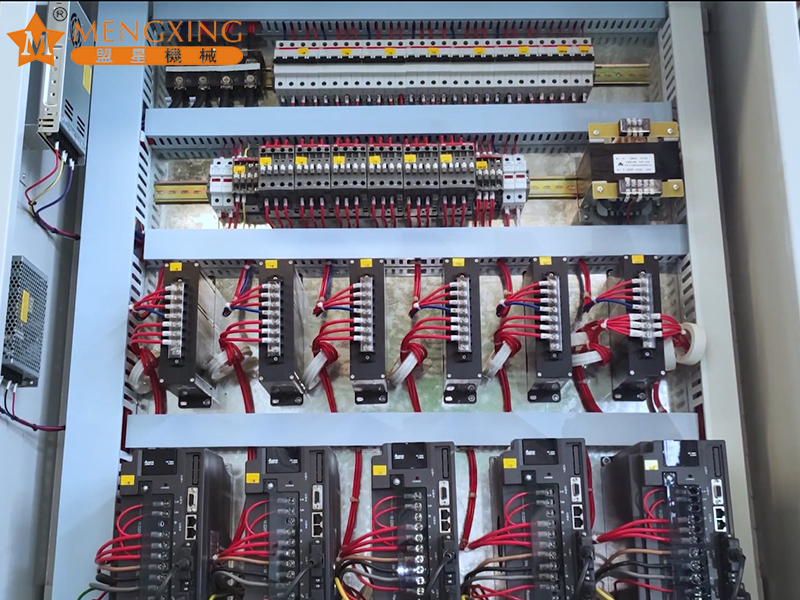

Technical Components

| PLC | Taiwan Delta |

| Touch Screen Monitor ( 15″inch /Color ) | Taiwan Delta |

| Feeding servo motor(5.5kw) | Taiwan Delta |

| Forming up/down mold servo motor(7.5kw/7.5kw) | Taiwan Delta |

| Cutting up/down mold servo motor(7.5kw/7.5kw) | Taiwan Delta |

| Stacking servo motor(2kw) | Taiwan Delta |

| Heater(288 pcs) | Germany Elstein |

| Contactor | Switzerland ABB |

| Thermo Relay | Switzerland ABB |

| Relay | Germany Weidmuller |

| SSR | Switzerland Carlo Gavazzi |

| Vacuum Pump | Germany Busch |

| Feeding Chain | Italy Regina |

| Automatic Lubrication System | Taiwan ChenYing |

| Electronic pressure sensor | Taiwan Delta |

| Pneumatic | JAPAN SMC |

| Cylinder | JAPAN SMC & Taiwan Airtac |

Why choose us

Our machines have been sold around the world. Great machine performance help to win customer’s trust and recommendation. We continue to invest in research and development in thermoforming and automated production. We are China’s pioneer and leader in this field. Is constantly striving to become a world-class manufacturer. We also welcome partners from other countries to join us and become our agents to jointly explore the market and serve our customers well.

Product technical, economic indicators have reached the national standard, comparable with foreign advanced type, in 2006 through the ISO9001:2000 quality management system certification, product best-selling domestic and foreign markets, deeply trusted by users.

Sample Pictures

Container Pictures

Product detail pictures:

Related Product Guide:

Our solutions are widely recognized and trusted by consumers and will meet up with constantly developing financial and social requires for factory Outlets for Semi Automatic Thermoforming Machine - MFC9070 3 Stations Thermoformer – Mengxing , The product will supply to all over the world, such as: Juventus, Germany, Turkmenistan, Our professional engineering group will always be ready to serve you for consultation and feedback. We're able to also offer you with absolutely free samples to meet your requirements. efforts will likely be produced to offer you the ideal service and goods. For anyone who is thinking about our company and merchandise, be sure to contact us by sending us emails or contact us quickly. As a way to know our merchandise and firm. lot more, you can come to our factory to find out it. We'll always welcome guests from all over the world to our business to build company relations with us. Be sure to feel free to get in touch with us for business and we believe we've been intending to share great trading practical experience with all our merchants.

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!