Fast delivery PET Pressure & Vacuum Forming Machine - XC100-130/125-WF Full-auto Cooling Tower Fill Making Machine – Mengxing

Fast delivery PET Pressure & Vacuum Forming Machine - XC100-130/125-WF Full-auto Cooling Tower Fill Making Machine – Mengxing Detail:

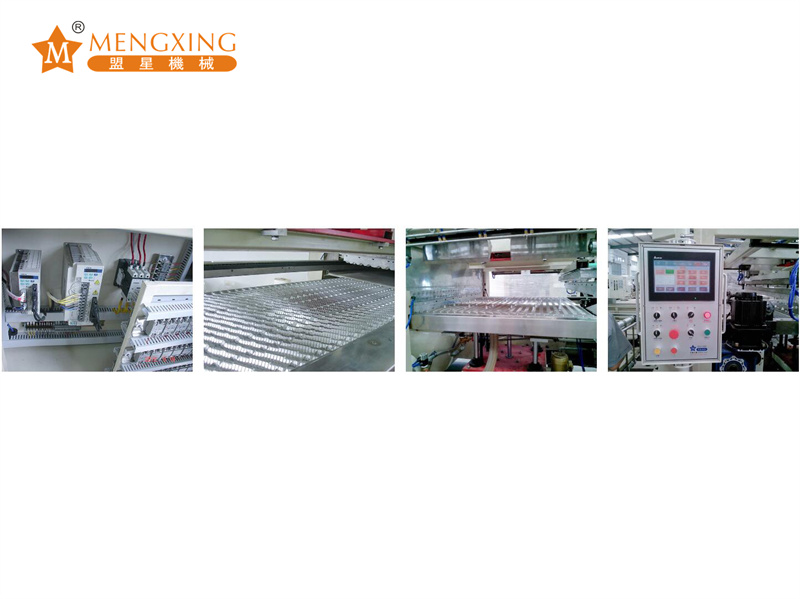

Machine Details

Usage

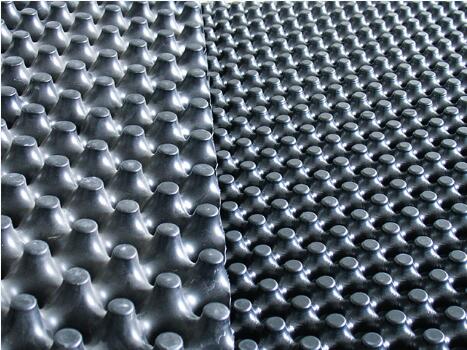

This vacuum forming machine is widely used for making vacuum formed products like cooling tower fills from PVC, PS, PP, EPS, PET, Bio-degradable material, APET, PETG and so on.

II,Operation Principle

Operation processes: The heated and soften plastic sheet are being vacuum formed in the mold in order to get the various finished products. The operation processes are: sheet-feeding—heated—forming—side trimming— crosscut.

Structure Feature

01. The machine is combined with pneumatic , mechanical and electricity driving, adopt PLC control . It can achieve sheet feeding , heating , forming , side trimming , crosscut into continuous job .

All working action can adjust uder non-stop production . It’s convenient and high capacity , easy for operation .

02. The working method can crosscut by different pattern of fill .

03. Servo motor feeding , feeding length stepless adjustabe , precision and reliable.

04. Cutting unit with servo motor driving , electrical & pneumatic adjustable by different length crosscut ( the length must be longer than each forming mold length ) .

05. Forming area is big and easy for mold installation & replace.

06. Cylinder roll sheet loading , feeding chain manual adjust.

07. Upper , lower mold stroke limited , up mold descend motor adjust.

08. Forming area double adjustable , can save the sheet material .

09. Back acting plate adopt double cylinder method , motor setting position .

10.Vacuum in two steps.

11. Fan blowing , air spray cooling device .

12. Heater adopt individual heating temperature control . ( Point to Point )

13. Advance sheet feeding , heating parameter can automatic adjust.

Technical Parameter

|

Parameter |

XC100-130/125-BWF (mode No.) |

|

| Suitable sheet width(mm) |

1000-1300 |

|

| Sheet thickness(mm) |

0.3-1 |

|

| Max.dia. of sheet roll (mm) |

600 |

|

| Up mold stroke(mm) |

300 |

|

| Down mold stroke(mm) |

250 |

|

| Max. forming area(mm2) |

1200×1200 |

|

| Max. forming height(mm) |

120 |

|

| Max. forming depth(mm) |

100 |

|

| Capacity (cycle/min) |

4-8 |

|

|

Product Shaping& Cooling |

Air vent qty. |

7PCS |

| Air sprayer qty. |

16PCS |

|

| Gas source (outlay) | Air supply (m3/min) |

≥3 |

| Pressure(MPa) |

0.8 |

|

| Water consumption |

4-5 Cube/Hour |

|

| Vacuum pump ( Outlay ) |

Busch R5 0100 |

|

| Power supply |

3-phase 4-wire 415V/ 220V 50Hz |

|

| Heating power(Kw) |

59.4 |

|

| Feeding motor power(Kw) |

3.0 |

|

| Power of whole machine(Kw) |

68.6 |

|

| Dimension(L×W×H)(mm) |

9600×3400×2500 |

|

| Weight(Kgs) |

7500 |

|

Technical ParameterV,Technical Configuration

| PLC |

Taiwan Delta |

| Touch screen monitor ( 10.4″inch /Color ) |

Taiwan Delta |

| Feeding motor(3.0kw) |

Taiwan Delta |

| Heater with probe(1pcs) |

Germany |

| Heater(99pcs) |

China |

| Solid voltage regulator |

China |

| Contactor |

Germany Siemens |

| Thermo relay |

Germany Siemens |

| Relay |

Japan Omron |

| Vacuum pump(2 set) |

Busch R5 0100 |

| Pneumatic component |

Japan SMC |

| Cylinder |

China |

| Air sprayer(8pcs) |

Meiji |

| Fan blower(4×0.55 Kw ) |

Manda |

Sample Pictures

Container Pictures

Product detail pictures:

Related Product Guide:

We have been also concentrating on enhancing the things management and QC method so that we could preserve terrific edge inside the fiercely-competitive enterprise for Fast delivery PET Pressure & Vacuum Forming Machine - XC100-130/125-WF Full-auto Cooling Tower Fill Making Machine – Mengxing , The product will supply to all over the world, such as: Libya, Tunisia, Sudan, Excellent quality, competitive price, punctual delivery and dependable service can be guaranteed. For further inquires please do not hesitate to contact us. Thank you - Your support continuously inspires us.

In China, we have purchased many times, this time is successful and satisfactory, a sincere and realiable Chinese manufacturer!