Good User Reputation for Pressure Thermoforming Machine - MCIM7660 2 Stations Thermoformer – Mengxing

Good User Reputation for Pressure Thermoforming Machine - MCIM7660 2 Stations Thermoformer – Mengxing Detail:

Machine Details

Applications

The machine is designed to produce thin-walled open packaging containers of various sizes with rolled sheet under the high-speed vacuum suction molding process. The products produced by this machine can be used for packaging food, tourism products, textiles, medical, toys, cosmetics, electrical appliances, household hardware, etc.

Suitable Sheet

Starch-deposit sheets, light-deposit sheet, environment sheet, APET, PETG. PVC, HIPS, PET, PS, OPS ,etc.

Structure Features

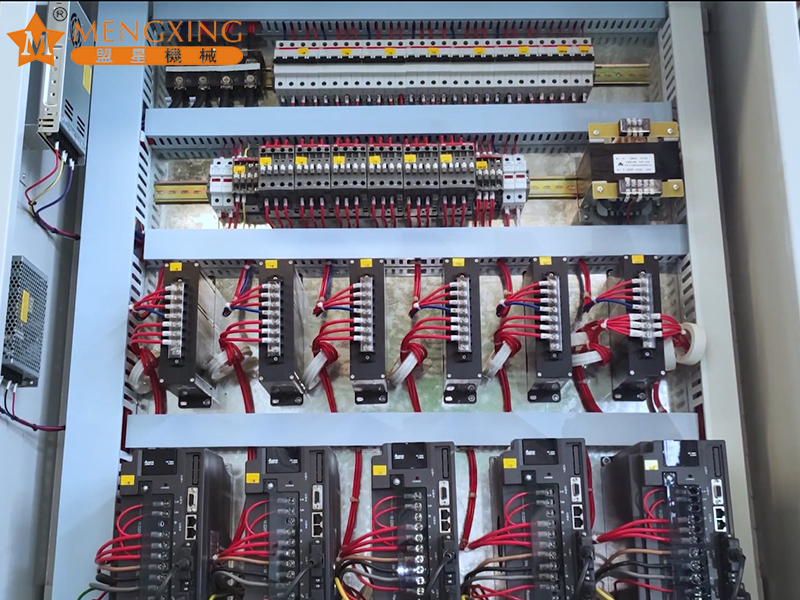

All working actions of mechanical, pneumatic and electrical combination are controlled by PLC. Touch screen makes operation easy.

Forming type: positive pressure and negative pressure vacuum forming

Up/down mold forming type.

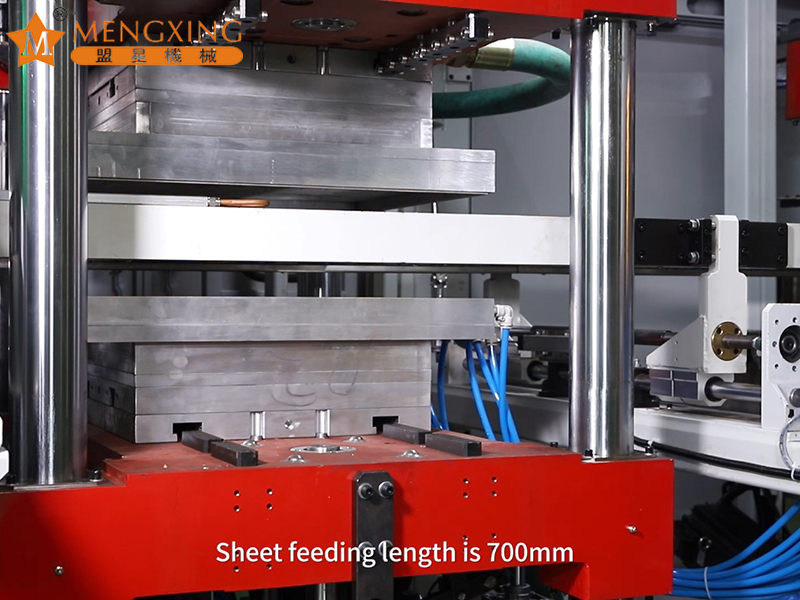

Servo motor feeding, feeding length can be adjusted steplessly. High speed and accuracy.

The upper heater is equipped with 4-section heating, and the lower heater is equipped with 3-section heating. With sheet edge preheating function.

For avoiding sheet broken issue, with sheet edge preheating function.

The heater is equipped with an intelligent temperature control system, which can automatically supply heating and separate heater control. Fast heating (heating from 0-400 ℃ for 3 minutes), not affected by external voltage

The forming and cutting station is controlled by the servo motor to open/close the mold, with high cutting accuracy. Product automatic accounting output.

Stacking type: downward stacking/manipulator stacking.

With products details and running data memorization function.

With quickly changing mold system, more efficient.

Feeding width can be synchronously or independently adjusted in electrical way.

Heater automatically push-out when the sheet is over heated.

Auto roll sheet loading, reduce the workload.

Technical Parameter

| Sheet width (mm) | 500-800 | |

| Sheet thickness (mm) | 0.2-1.5 | |

| Max sheet diameter (mm) | 800 | |

| Forming mould stroke (mm) | Up mould 140,Down mould 210 | |

| Locking mould force(ton) | 30 | |

| Max forming area (mm2) | 760×600 | |

| Min forming area (mm2) | 500×380 | |

| Forming mould width (mm) | 500-760 | |

| Forming mould length(mm) | 460-600 | |

| Max forming depth/height (mm) | Manipulator :90 /80;Downward stacking:175/125 | |

| Cutting force(ton) | 45 | |

| Stacking way | Downward stacking/Manipulator stacking | |

| Cycle time (cycle/ min) | Manipulator: Max18;Downward stacking:Max30 | |

| Cooling Outlet | Water cooling | |

| Air supply | Volume (m3/ min) | ≥5 |

| Pressure (MPa) | 0.8 | |

| Vacuum pump | Busch R5 0100 | |

| Power supply | 3 phase 4 lines 380V50Hz | |

| Heater power (kw) | 150 | |

| General power (kw) | 200 | |

| Dimension (L×W×H) (mm) | 10040×2600×3400 | |

| Weight ( Ton ) | ≈12 | |

Technical Configuration

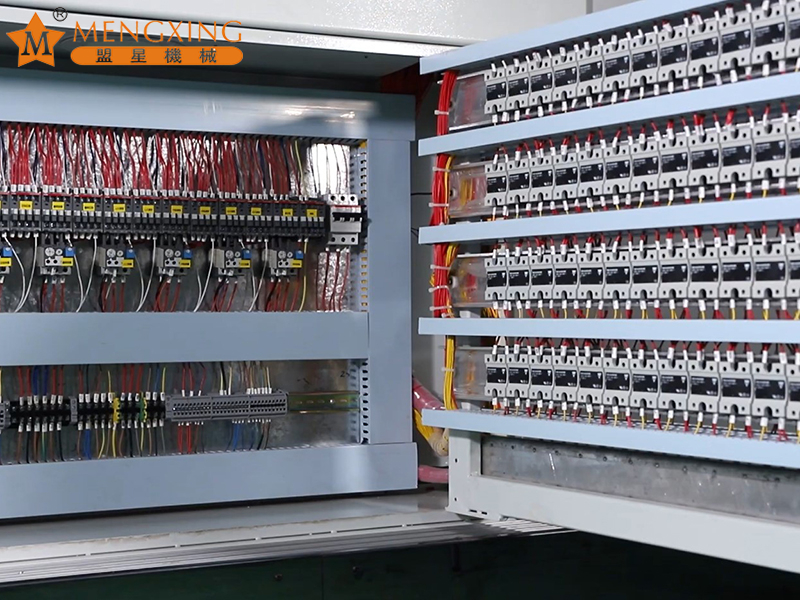

| PLC Controller | Taiwan Delta |

| Touch Screen Monitor ( 10.4″inch /Color ) | Taiwan Delta |

| Feeding servo motor(4.5kw) | Taiwan Delta |

| Forming up/down mould servo motor(5.5kw) | Taiwan Delta |

| Heater(250pcs) | Germany Elstein Or Ireland Ceramicx |

| Contactor | Germany Siemens |

| Thermo Relay | Germany Siemens |

| Relay | Germany Weidmuller |

| SSR | Switzerland Carlo Gavazzi |

| Vacuum Pump | Germany Busch |

| Pneumatic | JAPAN SMC |

| Cylinder | JAPAN SMC & Taiwan Airtec |

About Mengxing

We are a Chinese high-tech enterprise, running with ISO9001: 2018 quality management system certification.We are not only offer different solution to meet different customer’s production requirement, but also upgrade machine base on customers’ feedback.

Our primary product series include the HTJ cutting machine series, the XC series fully automatic high-speed vacuum forming machine, the XCH series of thick sheet vacuum forming machines, the MFC series multi stations Pressure & Vacuum forming machines, and the XCH series. suitable for making many types of sheets, including biodegradable, PLA, BOPS, PET, PVC, PS, and PP.

Sample Pictures

Container Pictures

Product detail pictures:

Related Product Guide:

We pursue the management tenet of Quality is remarkable, Company is supreme, Name is first, and will sincerely create and share success with all clientele for Good User Reputation for Pressure Thermoforming Machine - MCIM7660 2 Stations Thermoformer – Mengxing , The product will supply to all over the world, such as: Comoros, Karachi, Malaysia, Our products are mainly exported to Southeast Asia, the Middle East, North America and Europe. Our quality is surely guaranteed. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.