Rapid Delivery for Vacuum Forming Heater - XC100-130/125-WF Full-auto Cooling Tower Fill Making Machine – Mengxing

Rapid Delivery for Vacuum Forming Heater - XC100-130/125-WF Full-auto Cooling Tower Fill Making Machine – Mengxing Detail:

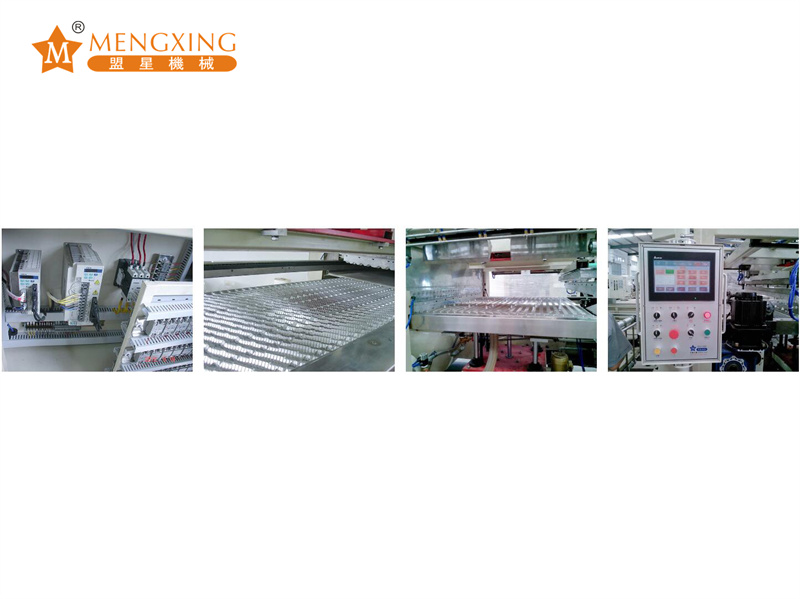

Machine Details

Usage

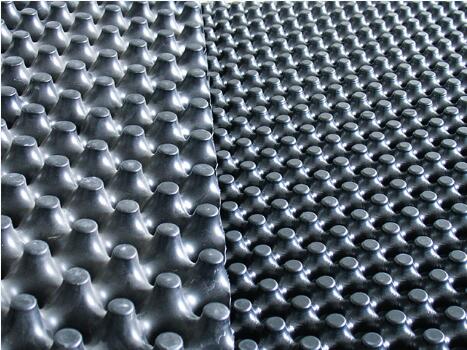

This vacuum forming machine is widely used for making vacuum formed products like cooling tower fills from PVC, PS, PP, EPS, PET, Bio-degradable material, APET, PETG and so on.

II,Operation Principle

Operation processes: The heated and soften plastic sheet are being vacuum formed in the mold in order to get the various finished products. The operation processes are: sheet-feeding—heated—forming—side trimming— crosscut.

Structure Feature

01. The machine is combined with pneumatic , mechanical and electricity driving, adopt PLC control . It can achieve sheet feeding , heating , forming , side trimming , crosscut into continuous job .

All working action can adjust uder non-stop production . It’s convenient and high capacity , easy for operation .

02. The working method can crosscut by different pattern of fill .

03. Servo motor feeding , feeding length stepless adjustabe , precision and reliable.

04. Cutting unit with servo motor driving , electrical & pneumatic adjustable by different length crosscut ( the length must be longer than each forming mold length ) .

05. Forming area is big and easy for mold installation & replace.

06. Cylinder roll sheet loading , feeding chain manual adjust.

07. Upper , lower mold stroke limited , up mold descend motor adjust.

08. Forming area double adjustable , can save the sheet material .

09. Back acting plate adopt double cylinder method , motor setting position .

10.Vacuum in two steps.

11. Fan blowing , air spray cooling device .

12. Heater adopt individual heating temperature control . ( Point to Point )

13. Advance sheet feeding , heating parameter can automatic adjust.

Technical Parameter

|

Parameter |

XC100-130/125-BWF (mode No.) |

|

| Suitable sheet width(mm) |

1000-1300 |

|

| Sheet thickness(mm) |

0.3-1 |

|

| Max.dia. of sheet roll (mm) |

600 |

|

| Up mold stroke(mm) |

300 |

|

| Down mold stroke(mm) |

250 |

|

| Max. forming area(mm2) |

1200×1200 |

|

| Max. forming height(mm) |

120 |

|

| Max. forming depth(mm) |

100 |

|

| Capacity (cycle/min) |

4-8 |

|

|

Product Shaping& Cooling |

Air vent qty. |

7PCS |

| Air sprayer qty. |

16PCS |

|

| Gas source (outlay) | Air supply (m3/min) |

≥3 |

| Pressure(MPa) |

0.8 |

|

| Water consumption |

4-5 Cube/Hour |

|

| Vacuum pump ( Outlay ) |

Busch R5 0100 |

|

| Power supply |

3-phase 4-wire 415V/ 220V 50Hz |

|

| Heating power(Kw) |

59.4 |

|

| Feeding motor power(Kw) |

3.0 |

|

| Power of whole machine(Kw) |

68.6 |

|

| Dimension(L×W×H)(mm) |

9600×3400×2500 |

|

| Weight(Kgs) |

7500 |

|

Technical ParameterV,Technical Configuration

| PLC |

Taiwan Delta |

| Touch screen monitor ( 10.4″inch /Color ) |

Taiwan Delta |

| Feeding motor(3.0kw) |

Taiwan Delta |

| Heater with probe(1pcs) |

Germany |

| Heater(99pcs) |

China |

| Solid voltage regulator |

China |

| Contactor |

Germany Siemens |

| Thermo relay |

Germany Siemens |

| Relay |

Japan Omron |

| Vacuum pump(2 set) |

Busch R5 0100 |

| Pneumatic component |

Japan SMC |

| Cylinder |

China |

| Air sprayer(8pcs) |

Meiji |

| Fan blower(4×0.55 Kw ) |

Manda |

Sample Pictures

Container Pictures

Product detail pictures:

Related Product Guide:

Our mission should be to turn out to be an innovative supplier of high-tech digital and communication devices by furnishing benefit added design and style, professional manufacturing, and repair capabilities for Rapid Delivery for Vacuum Forming Heater - XC100-130/125-WF Full-auto Cooling Tower Fill Making Machine – Mengxing , The product will supply to all over the world, such as: Mecca, Malaysia, Malaysia, Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound solutions with good logistics service and economical cost. Depending on this, our solutions are sold very well in the countries in Africa, the Mid-East and Southeast Asia.

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.