Short Lead Time for Blister Thermoforming Machine - MFPC7660 4 Stations Thermoformer – Mengxing

Short Lead Time for Blister Thermoforming Machine - MFPC7660 4 Stations Thermoformer – Mengxing Detail:

Machine Details

Usage

The machine is designed for producing various of open-wide plastic containers, such as food trays, plastic trays, cosmetic trays , blister , clamshells , plates and other plastic related items .

Suitable Sheet

PVC, PP, PS, OPS, PET, APET, PETG, CPET Etc

Structure Features

Mechanical, pneumatic and electrical combination, all working actions are controlled by PLC. Touch screen makes the operation convenient and easy.

Forming type: pressure and vacuum forming

Up/down mould forming type.

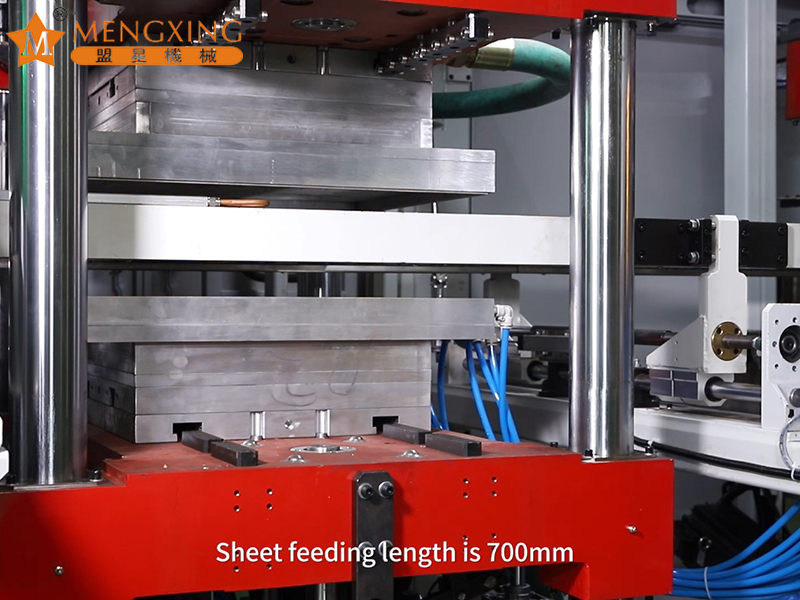

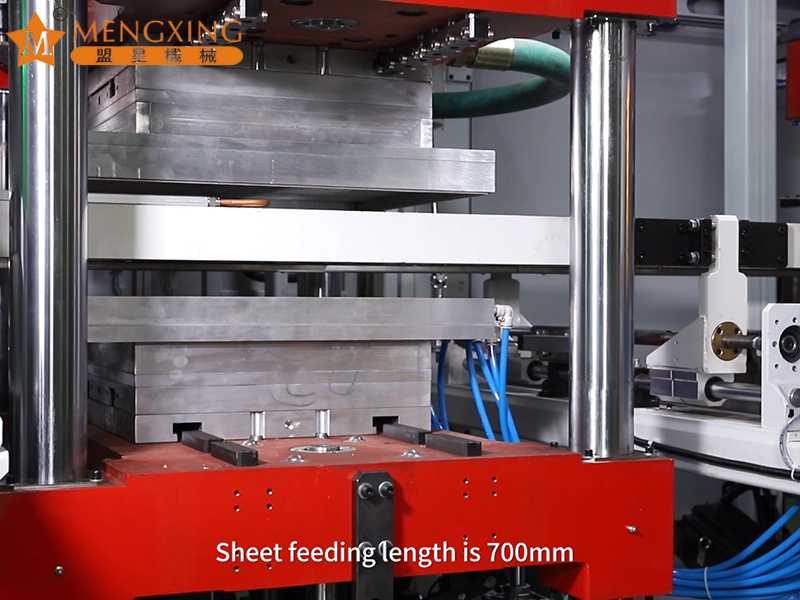

Servo motor feeding, feeding length can be step-less adjusted. High speed and accurate.

Up heater with 4 sections heating, down heater with 3 sections heating. With sheet edge preheating.

With sheet edge preheating. Avoid sheet broken.

Heater with intellectual temperature control system, automatic supply the heating individual heater control. Fast heating(3 min from 0-400 degree), it won’t be effected by outer voltage

Forming and cutting station open/close mould controlled by servo motor, high cutting precision. products automatically accounting output.

Stacking type: downward stacking/manipulator stacking.

With products details and running data memorization function.

With quickly changing mould system, , more efficient.

Feeding width can be synchronously or independently adjusted in electrical way.

Heater automatically push-out when the sheet is over heated.

Auto roll sheet loading, reduce the working load.

Technical Parameter

| Sheet width (mm) | 500-800 | |

| Sheet thickness (mm) | 0.2-1.5 | |

| Max sheet diameter (mm) | 800 | |

| Forming mould stroke (mm) | Up mould 140,Down mould 210 | |

| Locking mould force(ton) | 30 | |

| Max forming area (mm2) | 760×600 | |

| Min forming area (mm2) | 500×380 | |

| Forming mould width (mm) | 500-760 | |

| Forming mould length(mm) | 460-600 | |

| Max forming depth/height (mm) | Manipulator :90 /80;Downward stacking:175/125 | |

| Cutting force(ton) | 45 | |

| Stacking way | Downward stacking/Manipulator stacking | |

| Cycle time (cycle/ min) | Manipulator: Max18;Downward stacking:Max30 | |

| Cooling Outlet | Water cooling | |

| Air supply | Volume (m3/ min) | ≥5 |

| Pressure (MPa) | 0.8 | |

| Vacuum pump | Busch R5 0100 | |

| Power supply | 3 phase 4 lines 380V50Hz | |

| Heater power (kw) | 150 | |

| General power (kw) | 200 | |

| Dimension (L×W×H) (mm) | 10040×2600×3400 | |

| Weight ( Ton ) | ≈12 | |

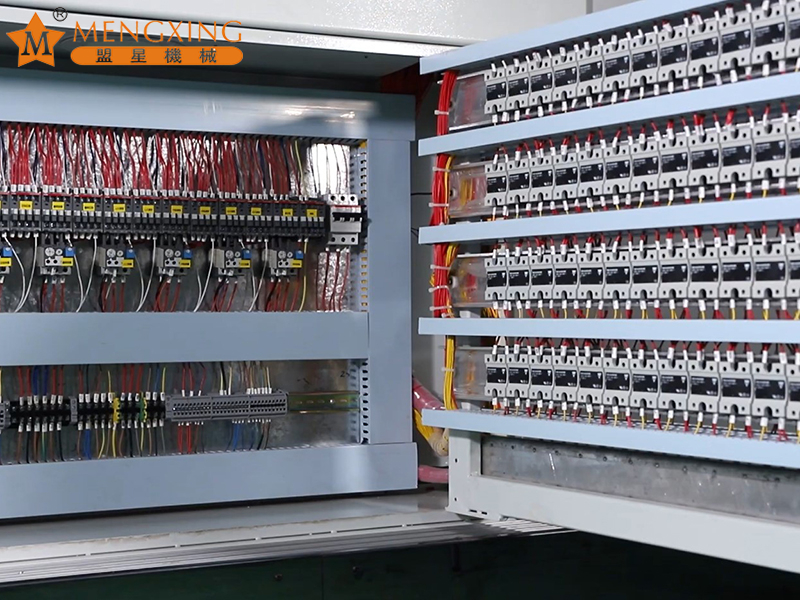

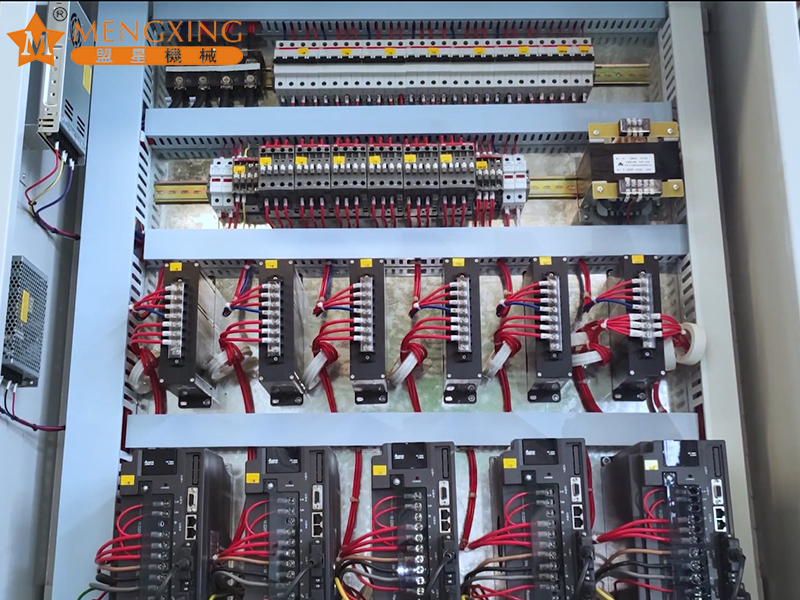

Technical Components

| PLC Controller | Taiwan Delta |

| Touch Screen Monitor ( 10.4″inch /Color ) | Taiwan Delta |

| Feeding servo motor(4.5kw) | Taiwan Delta |

| Forming up/down mould servo motor(5.5kw) | Taiwan Delta |

| Heater(250pcs) | Germany Elstein Or Ireland Ceramicx |

| Contactor | Germany Siemens |

| Thermo Relay | Germany Siemens |

| Relay | Germany Weidmuller |

| SSR | Switzerland Carlo Gavazzi |

| Vacuum Pump | Germany Busch |

| Pneumatic | JAPAN SMC |

| Cylinder | JAPAN SMC & Taiwan Airtec |

Why choose us

The company’s main product series: XC series full-automatic high-speed vacuum forming machine, XCH series thick film vacuum forming machine, MFC series multi station pressure vacuum forming machine, HTJ series cutting machine. It is applicable to the molding of PET, PVC, PS, PP, biodegradable, PLA, BOP and other different plates.

Sample Pictures

Container Pictures

Product detail pictures:

Related Product Guide:

Persisting in High quality, Prompt Delivery, Aggressive Price, we have established long-term cooperation with clientele from both equally overseas and domestically and get new and old clients' higher comments for Short Lead Time for Blister Thermoforming Machine - MFPC7660 4 Stations Thermoformer – Mengxing , The product will supply to all over the world, such as: Hamburg, Montreal, Boston, We believe that good business relationships will lead to mutual benefits and improvement for both parties. We have established long-term and successful cooperative relationships with many customers through their confidence in our customized services and integrity in doing business. We also enjoy a high reputation through our good performance. Better performance will be expected as our principle of integrity. Devotion and Steadiness will remain as ever.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.